ProductPRODUCTS

Single Sphere Rubber Bellows KF-9100

Product Feature

The rubber joint can greatly reduce pipeline system vibration and noise, can solve the problem of joint displacement, axial expansion, etc.

According to different materials, it can be made into many kinds, adapt to many mediums and different environment.

Good sealing rubber, light weight, easy installation, long service life, and avoid contacting with sharp metal device.

If use overhead, can match with elastic support.

If pipeline pressure is high, should use bolt connect the flange both ends.

Technical Parameters

Nominal diameter(mm) | 32~1200 | 32~1200 | ||

Nominal pressure(Mpa) | 1.0 | 1.6 | ||

Testing pressure | Seal(Mpa) | 1.1 | 1.76 | |

Suitable temperature(°C) | -20°C~120°C | |||

Suitable medium | Drinking water、sewage、seawater、food、medicines、gas、oil and acid | |||

Main Raw Material

Flange | WCB Cold/Hot Galvanizing | |||

Joint | EPDM/NBR | |||

Reference Standard

Testing standard | API 598 | ||||

End flange standard | DIN PN10 / PN16、ANSI 125# / 150#、BS4504 PN10 / PN16 |

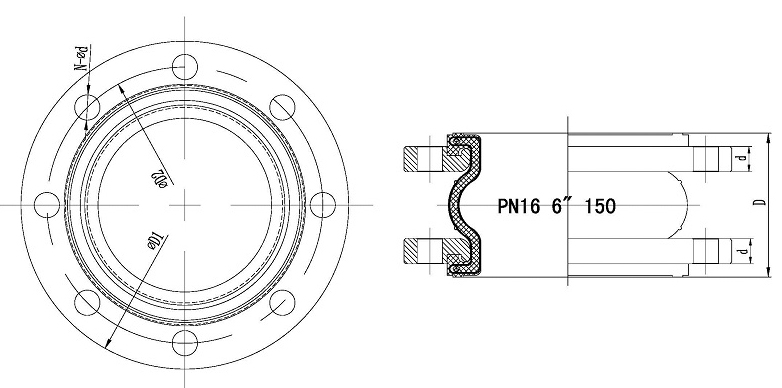

Overall Dimension and Weight

Size | ΦD1 | ΦD2 | N-Φd | D | d | Extension | Compression | Horizontal displacement (mm) | Deflexion angle | Weight (kg) |

DN32 | 140 | 100 | 4-18 | 95 | 16 | 6 | 9 | 9 | 15° | 3.4 |

DN40 | 150 | 110 | 4-18 | 95 | 18 | 6 | 10 | 9 | 15° | 4 |

DN50 | 165 | 125 | 4-19 | 105 | 18 | 7 | 10 | 10 | 15° | 5.5 |

DN65 | 185 | 145 | 4-19 | 115 | 20 | 7 | 13 | 11 | 15° | 6.7 |

DN80 | 200 | 160 | 8-19 | 135 | 20 | 8 | 15 | 12 | 15° | 7.7 |

DN100 | 220 | 180 | 8-19 | 150 | 22 | 10 | 19 | 13 | 15° | 9.4 |

DN125 | 250 | 210 | 8-19 | 165 | 24 | 12 | 19 | 13 | 15° | 12.7 |

DN150 | 285 | 240 | 8-23 | 180 | 24 | 12 | 20 | 14 | 15° | 15.8 |

DN200 | 340 | 295 | 12-23 | 210 | 24 | 16 | 25 | 22 | 15° | 20 |

DN250 | 405 | 355 | 12-28 | 230 | 28 | 16 | 25 | 22 | 15° | 29.22 |

DN300 | 460 | 410 | 12-28 | 245 | 28 | 16 | 25 | 22 | 15° | 32.8 |

DN350 | 520 | 470 | 16-28 | 255 | 28 | 16 | 25 | 22 | 15° | 41.3 |

DN400 | 580 | 525 | 16-31 | 255 | 30 | 16 | 25 | 22 | 15° | 55.6 |

DN450 | 640 | 585 | 20-31 | 255 | 30 | 16 | 25 | 22 | 15° | 61.8 |

DN500 | 715 | 650 | 20-34 | 255 | 32 | 16 | 25 | 22 | 15° | 69.4 |

DN600 | 840 | 770 | 20-37 | 260 | 36 | 16 | 25 | 22 | 15° | 96.8 |

DN700 | 910 | 840 | 24-37 | 320 | 36 | 16 | 25 | 22 | 15° | |

DN800 | 1025 | 950 | 24-41 | 340 | 36 | 16 | 25 | 22 | 15° | |

DN900 | 1125 | 1050 | 28-41 | 370 | 36 | 16 | 25 | 22 | 15° | |

DN1000 | 1255 | 1170 | 28-44 | 400 | 36 | 18 | 26 | 24 | 15° | |

DN1200 | 1485 | 1390 | 32-50 | 420 | 36 | 18 | 26 | 24 | 15° |

Back to list

Back to list